Showing Food Packaging Operations: How Automated Machines Boost Efficiency

In today's fast-paced world, the food industry faces immense pressure to meet growing consumer demands while maintaining high-quality products and operational efficiency. One critical aspect of the food industry is packaging, as it directly impacts product freshness, shelf life, and overall presentation. Traditional manual packaging processes can be time-consuming, labor-intensive, and prone to human errors, leading to inefficiencies and increased costs. However, with advancements in technology, automated food packaging machines have emerged as a game-changer for food manufacturers. In this blog, we will explore how automated machines, such as coffee packaging machines, dough divider rounder machines, horizontal packing machines, cartoner packaging machines, and spice powder packing machines, are transforming the food packaging industry, streamlining operations, and boosting overall efficiency.

The Rise of Automation in Food Packaging

Automation has revolutionized various industries, and the food packaging sector is no exception. As consumer preferences shift towards convenience and ready-to-use products, the demand for faster and more efficient packaging processes has grown exponentially. Automated food packaging machines offer significant advantages over manual methods, including reduced production time, minimized product wastage, increased accuracy, and enhanced product safety. Let's delve into some specific automated machines and their role in streamlining food packaging operations.

Ensure Freshness and Flavor

Coffee, one of the world's most beloved beverages, requires special attention when it comes to packaging. To preserve the aroma and flavor of coffee, it is essential to prevent exposure to air and moisture. Coffee packaging machines are designed to efficiently seal coffee grounds or beans in airtight packages, maintaining product freshness for an extended period. These machines use advanced technologies, such as nitrogen flushing, to remove oxygen from the packaging, further prolonging the shelf life of the coffee. By automating the coffee packaging process, manufacturers can ensure consistent quality and meet consumer demands efficiently.

Speeding Up Bakery Operations

Bakeries often face the challenge of maintaining uniformity in their products while keeping up with high demand. The dough divider rounder machine has become an indispensable asset for bakeries seeking to streamline their operations. These automated machines efficiently portion and round the dough, ensuring consistent sizes and shapes for bread, buns, and other baked goods. With precise measurements and rapid processing capabilities, dough divider rounder machines not only save time but also reduce labor costs and minimize product inconsistencies.

Versatility and Speed in Packaging

A horizontal packing machine is a versatile automated system widely used in the food industry. These machines can handle a variety of products, including snacks, candies, biscuits, and more. By employing a horizontal form-fill-seal process, they create pouches or bags from rolls of packaging material, fill them with the product, and then seal them tightly. The ability to handle different types of packaging materials and adjust packaging sizes swiftly makes horizontal packing machines an ideal choice for manufacturers dealing with a diverse range of products. Their high-speed operation enables food companies to meet tight production schedules without compromising on quality.

Simplifying Secondary Packaging

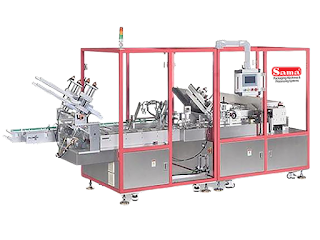

Once products are individually packaged, they often need to be grouped together for distribution and retail display. This is where cartoner packaging machine came into play. These automated machines efficiently load individual packages into cartons, creating secondary packaging that ensures products remain protected during transit. Cartoner packaging machines are highly adaptable and can handle various carton sizes and styles. By automating the cartoning process, manufacturers can significantly increase packaging speed, reduce manual labor requirements, and minimize errors.

Precision and Cleanliness

Spices add flavor and character to dishes, but their potency can be compromised by exposure to air, light, and moisture. Spice powder packing machine is specifically designed to tackle this challenge by maintaining the freshness and quality of spices. These automated machines precisely measure and fill spice powders into sealed pouches or containers, preventing contamination and ensuring accurate portions. Additionally, spice powder packing machines are equipped with dust extraction systems, keeping the packaging area clean and complying with stringent hygiene standards.

Advantages of Adopting Automated Food Packaging Machines

The adoption of automated food packaging machines offers numerous benefits that directly contribute to a food manufacturer's success:

- Improved Efficiency: Automated machines significantly reduce production time, allowing manufacturers to meet tight deadlines and high demand without compromising quality. m

- Enhanced Product Safety: Automation reduces the risk of contamination, ensuring that food products are safe for consumption and comply with industry regulations.

- Labor Cost Savings: By automating packaging processes, businesses can reduce manual labor requirements, thus optimizing workforce utilization and lowering labor costs.

- Minimized Product Wastage: Automated machines are highly accurate, resulting in reduced product wastage, which can be particularly crucial for expensive or perishable items.

- Consistent Product Quality: Automation ensures that each product is packaged identically, maintaining consistent quality and improving overall customer satisfaction.

- Increased Flexibility: Many automated machines are designed to handle various packaging materials and product types, providing manufacturers with the flexibility to diversify their product offerings.

Conclusion

The food packaging industry is rapidly evolving, with automation taking center stage to meet the growing demands of consumers and manufacturers alike. Automated food packaging machines, such as coffee packaging machines, dough divider rounder machines, horizontal packing machines, cartoner packaging machines, and spice powder packing machines, offer numerous advantages in terms of efficiency, product safety, and cost savings. Embracing these technologies is no longer a luxury but a necessity for food businesses seeking to stay competitive and enhance their position in the market. By streamlining food packaging operations through automation, manufacturers can ensure that their products reach consumers in optimal condition, driving customer satisfaction and loyalty.

.jpg)

The implementation of automated packaging has greatly benefited food packaging operations, boosting production efficiency in the food packaging industry.

ReplyDelete